PPAP

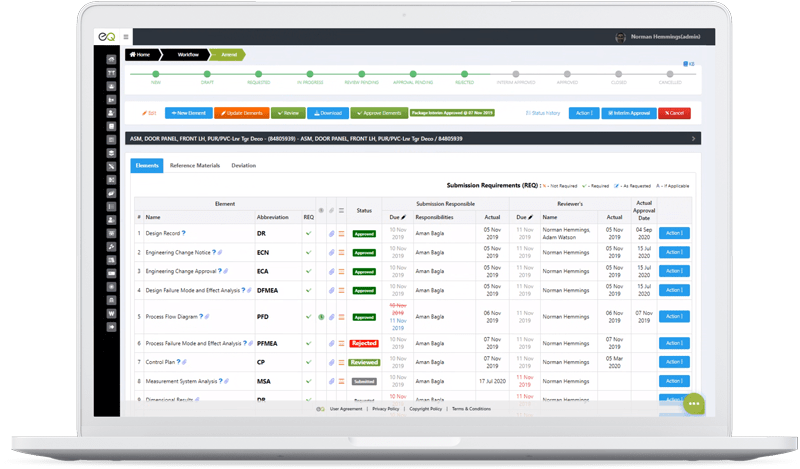

Effectively manage PPAPs globally with onsite and offsite support.

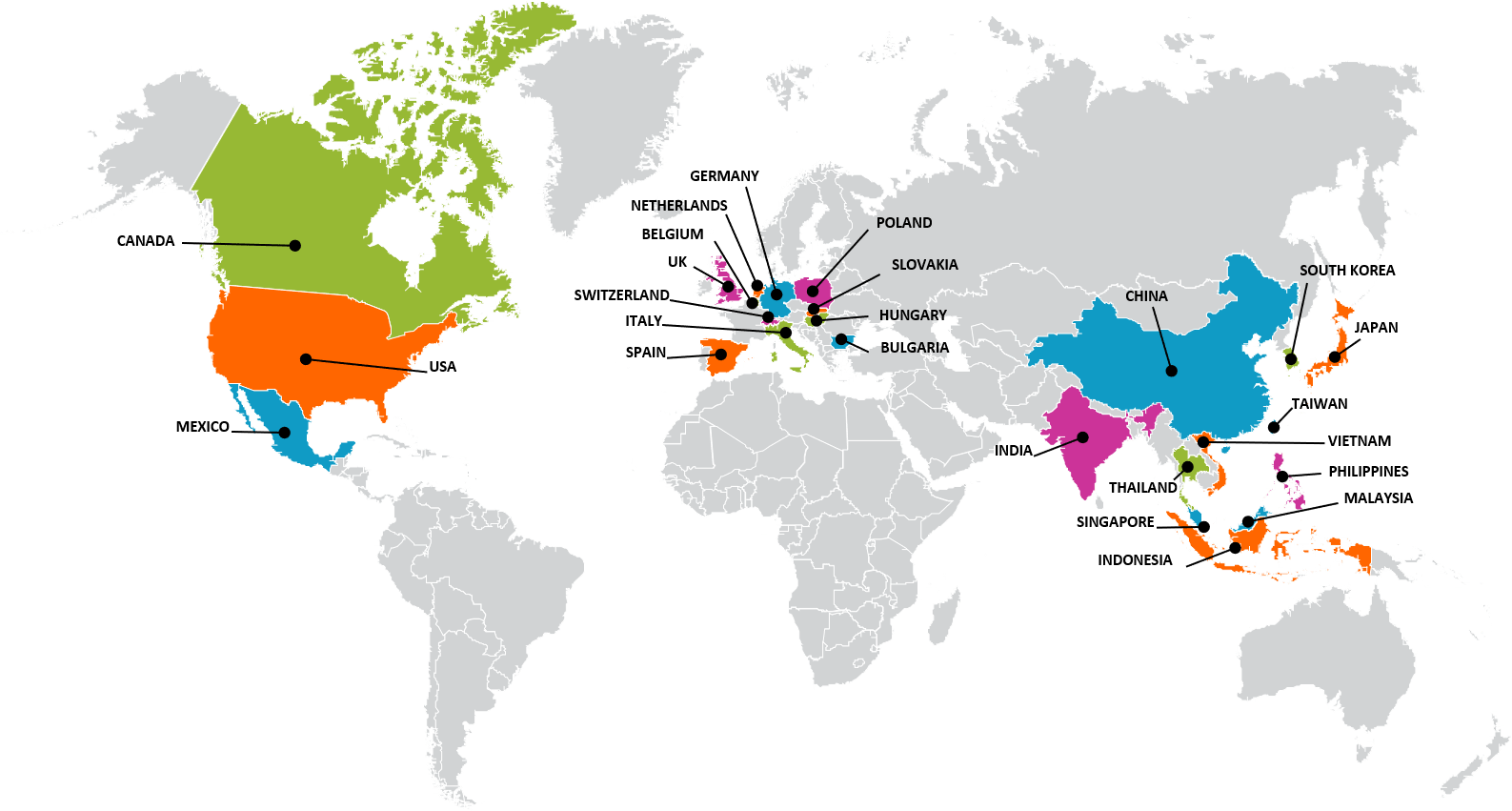

Get the expertise and the global reach you need to effectively manage your PPAP requirements with PPAP services. We have already delivered over 30,000 PPAPs for our clients and their suppliers, including onsite support in the following 25 countries: USA, Canada, Mexico, United Kingdom, Germany, Belgium, Netherlands, Switzerland, Italy, Spain, Poland, Hungary, Bulgaria, Slovakia, China, India, South Korea, Japan, Taiwan, Vietnam, Thailand, Philippines, Malaysia, Singapore, Indonesia, and expanding.

Our team of degreed, experienced, trained, and certified quality engineers will conduct the production part approval process per client and/or industry requirements.